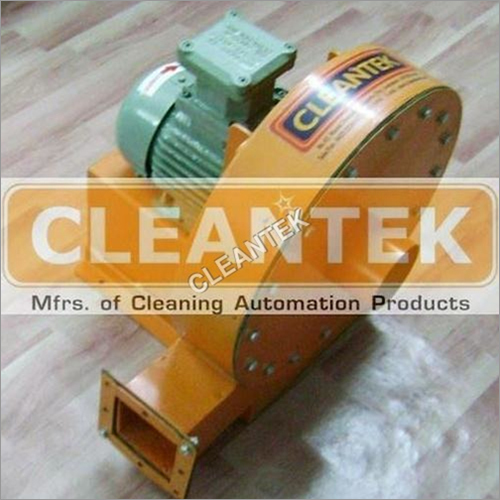

About Side Channel Blower

Holding in-depth domain expertise and wide shipping modes, we are noted as one of the cardinal manufacturers and suppliers of Side Channel Blower. These channel blowers are manufactured at our well equipped manufacturing unit using tested quality materials. Available with low shocking motion facility, these blowers are broadly used in water treatment plant and pneumatic conveying applications. Well-known among our clients due to its excellent durability, fine finish and high efficiency, our Side Channel Blower is delivered to clients within specified time frame.

Features of Side Channel Blower:

- Durable

- Low shocking motion

These ring blowers find applications in following field :

- Water treatment plant

- Candy manufacturing

- Pneumatic conveying

- Vacuum Lifting & Hold Down

- Dust collection

- Air Knife systems

- Plating equipments

- Dental suction unit

- Parts Drying

- Gloves checking

- Vacuum loaders

- Chemical & plating tank agitation

- Combustion air supply

- Paper trim removal.

High Performance & VersatilityThe Side Channel Blower is tailored to deliver reliable performance across a wide range of industries including printing, food processing, aquaculture, and medical applications. Its automatic operation, various mounting options, and support for both clockwise and counterclockwise rotation ensure compatibility with diverse system requirements.

Robust Construction & SafetyBuilt from premium aluminium alloy, this blower is rugged and corrosion-resistant, ensuring longevity even in challenging environments. Featuring sealed ball bearings and an IP55 enclosure, it offers maximum protection against dust, moisture, and other external contaminants for safe, extended use.

FAQs of Side Channel Blower:

Q: How do I install the Side Channel Blower in my facility?

A: The blower is designed for base mounting and supports both clockwise (CW) and counterclockwise (CCW) rotation directions, allowing flexible installation options. Please ensure its secured on a stable, flat surface and connected to a 230V, 50 Hz power supply. For safety and optimal performance, installation should follow the manufacturers guidelines provided in the manual.

Q: What industries or processes can benefit from using this blower?

A: This side channel blower is suitable for a range of applications including printing, food processing, air conveying, aquaculture, packaging, and medical systems. Its robust construction and air-cooled, automatic operation make it ideal for environments requiring consistent airflow and pressure.

Q: What are the benefits of the IP55 enclosure and sealed ball bearings?

A: The IP55-rated enclosure protects the blower against dust and low-pressure water jets, ensuring durability in harsh settings. Sealed ball bearings reduce maintenance needs while ensuring smooth operation and extending equipment lifespan.

Q: When should I consider using a single-stage versus a double-stage blower?

A: Single-stage blowers are typically used when moderate pressure and higher flow rates are needed, while double-stage configurations are suitable for when higher pressures at the same flow rate are required. Choose based on your specific applications demand for pressure and volume.

Q: Where can this blower be installed for best results?

A: Thanks to its IP55 enclosure and robust paint finish, the Side Channel Blower can be installed in indoor and covered outdoor environments. It performs best in clean, well-ventilated areas that allow adequate clearance for air cooling and maintenance access.

Q: How long does the blower typically last, and what maintenance is required?

A: With an average lifespan of five years, the blower requires minimal maintenance due to its sealed ball bearings and air-cooled design. Regular cleaning of the external surfaces and checking for obstructions in airflow will help maintain optimal performance.

Q: What makes this blower energy-efficient for continuous operation?

A: Operating at a motor power of 2.2 kW and a speed of 2800 rpm, coupled with the high-quality aluminium construction and automatic control, ensures energy-efficient and reliable continuous operation. The air-cooled system also prevents overheating, enhancing efficiency and safety.